TecAfrica Solutions

NW-WT100 Double Wall Paster

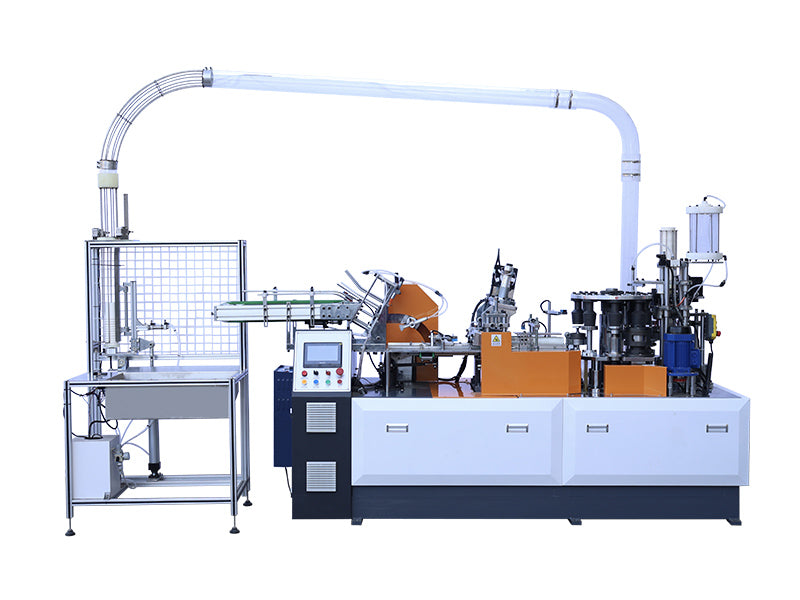

NW-WT100 Double Wall Paster

Couldn't load pickup availability

Product Application:

The externally pasted hollow corrugated paper cup machine adopts a table layout, isolating the transmission parts and molds. The transmission parts are under the table and the molds are on the table. This layout is convenient for cleaning and maintenance. The machine adopts automatic spray lubrication, longitudinal axis transmission structure, barrel-type cylindrical indexing mechanism and gear transmission to ensure the stability and quality of the whole machine. For electrical components, PLC, photoelectric tracking and servo feeding are used to control the operation. Suitable for the production of cold/hot cup externally pasted hollow corrugated.

The externally pasted hollow corrugated paper cup machine adopts a table layout, isolating the transmission parts and molds. The transmission parts are under the table and the molds are on the table. This layout is convenient for cleaning and maintenance. The machine adopts automatic spray lubrication, longitudinal axis transmission structure, barrel-type cylindrical indexing mechanism and gear transmission to ensure the stability and quality of the whole machine. For electrical components, PLC, photoelectric tracking and servo feeding are used to control the operation. Suitable for the production of cold/hot cup externally pasted hollow corrugated.

Technical Parameter:

|

Model |

NW-WT100 |

D1:ф50-90mm D2:ф40-70mm H:50-135mm |

|

Production speed |

80-100 pcs/min |

|

|

Voltage |

Three phase 380V /50HZ |

|

|

Machine host size |

L:2880* W:1060*H:1650mm |

|

|

Machine requirements |

Double Wall Paster |

|

|

Power |

5.5Kw |

|

|

Machine weight |

NW:2000KG |

|

|

Corresponding paper cup size |

6-16oz |

|

|

Speed |

80-100 g/㎡ |

|

|

Paper thickness requirements |

180-330 g/㎡ |

|

|

Gas supply requirements |

0.6-0.8 mpa 0.5m³/min |

|

|

Machine packaging size |

L:2980* W:1160 H:2000mm |

|

|

Cup body bonding method |

Ultrasonic |

|

|

Bottom roll flower |

L:1000*W:980*H:1900 |

Main features:

● Multi-model modules. Use simple window prompts for guidance and select the model to set.

● Flexible parameter settings. You can back up, restore or restore parameters to the factory. You can also modify the parameters manually in detail.

● Flexible encoder origin setting and direction automatic setting and fault self-checking. The hardware installation of the encoder does not need to consider the position, just set the software.

● Automatically configure the parking space, and it will be fast and low in less than one circle. After configuration, the machine will automatically calculate the inertia distance of the machine, and the position after deceleration will be at least one step faster.

● Hardware monitoring system. PLC output points, relays, contactors, PLC and touch screen, PLC and computer, PLC has an extended line real-time monitoring function, and the abnormal alarm in the touch screen prompts the cause of the fault. Detailed hardware and software fault information, users can easily troubleshoot according to the prompts.

Share